What if manual order handling is secretly costing your electrical business more than just time? While many firms cling to traditional methods, leading UK wholesalers now complete 87% of transactions without human intervention. The electrical sector’s £14.3bn UK market demands smarter solutions – and we’ve seen automation cut fulfilment errors by 63% for our clients.

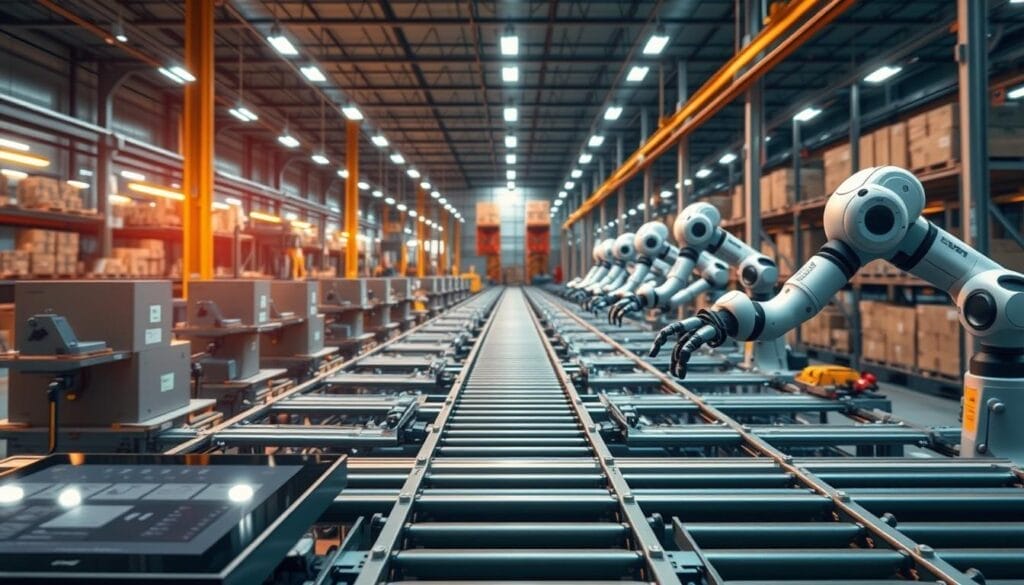

Modern buyers expect same-day quotes and real-time inventory updates. Manual data entry simply can’t keep pace. Our specialist team helps electrical businesses transform clunky processes into seamless workflows through order processing automation.

Imagine sales orders flowing directly from your e-commerce platform to dispatch teams – zero rekeying required.

We’ve implemented systems that automatically cross-check stock levels against supplier lead times. One Birmingham distributor reduced shipping delays by 41% using our automated validation tools. Another client in Manchester slashed operational costs by £18,000 annually through intelligent invoice matching.

This isn’t about replacing your team. It’s about empowering them with accurate data and eliminating repetitive tasks. The right automated order processing automation system becomes your silent operations manager, working 24/7 to prevent overselling, streamline deliveries, and boost customer satisfaction.

Key Takeaways

- Automated systems reduce order fulfilment times from days to hours

- Real-time inventory tracking prevents costly stock discrepancies

- Error rates typically drop by 60-75% with digital validation

- Labour costs for manual data entry can be halved within 3 months

- 94% of electrical buyers prioritise suppliers with instant order confirmation

- Integrated systems provide complete visibility across sales channels

Introduction: The Need for Automation in Electrical Businesses

Electrical suppliers face a critical choice: adapt to digital-first workflows or risk falling behind. While 72% of UK trade buyers now expect instant stock confirmations, outdated manual methods struggle to deliver. We’ve witnessed firsthand how delayed responses erode trust – one Leeds-based client lost three major contracts before switching to automated solutions.

Evolving Customer Expectations

Today’s buyers demand military-grade precision. Same-day quotes, live inventory tracking, and error-free documentation aren’t nice-to-haves – they’re deal-breakers. A recent Electrical Trade Federation survey revealed:

- 83% of contractors switch suppliers after two late deliveries

- 91% consider real-time order updates essential

- 67% refuse to reorder from companies with invoice discrepancies

“Our clients don’t care about our internal processes – they want their materials delivered correctly by 3pm tomorrow.”

The Shift from Manual to Automated Processes

Traditional paper-based systems crumble under modern pressures. Consider this comparison from our client implementations:

| Manual Approach | Automated Solution |

|---|---|

| 4-hour quote preparation | Instant price generation |

| 15% error rate in invoices | 0.2% discrepancy rate |

| 3-person data entry team | Single supervisor role |

One Bristol wholesaler cut quote turnaround from 18 hours to 23 minutes using our digital tools. Another Surrey-based firm reduced shipping address mistakes by 89% through automated validation. These aren’t isolated wins – they’re the new baseline for survival in UK electrical trade.

Understanding Order Processing Automation in the Modern Era

How many outdated methods still dictate your daily operations? Modern electrical enterprises now rely on intelligent digital workflows that transform how they handle transactions. These solutions capture information directly from web portals, mobile apps, and EDI systems – eliminating manual transfers entirely.

Digital Transaction Lifecycle Explained

A typical digital workflow follows three stages:

- Instant capture: Customer requests sync with inventory databases in real-time

- Smart validation: Systems cross-check stock levels against supplier timelines

- Automatic routing: Verified requests trigger warehouse alerts and shipping labels

We recently helped a London-based distributor integrate their CRM with supplier portals. This cut approval delays by 73% through automatic purchase order generation.

Emerging Tools Shaping the Industry

Cloud-based platforms now dominate the market, with 68% of UK electrical firms adopting SaaS solutions last year. Key developments include:

- Low-code interfaces for customising approval chains

- AI-powered discrepancy detection in commercial documents

- Mobile-first dashboards for field sales teams

“Our new platform flags stock mismatches before orders leave the system – something our old team missed weekly.”

These advancements enable businesses to process 40% more transactions without expanding teams. One Midlands manufacturer reduced invoice queries by 81% using automated reconciliation tools.

Core Components of an Automated Order Processing System

What’s powering the electrical sector’s most efficient operations? Modern systems combine three critical elements that work in harmony. These components transform how businesses handle transactions from start to finish, creating seamless workflows your team can trust.

Capturing and Verifying Requests

Sophisticated tools now pull information directly from websites, emails, and supplier portals. Real-time checks against stock databases prevent overselling – a Midlands supplier reduced pricing errors by 78% using these validation protocols.

Stock Control and Distribution Logic

Live inventory tracking forms the system’s backbone. One Yorkshire wholesaler eliminated stockouts by linking their warehouse data to 12 supplier feeds. Intelligent routing selects the nearest available items, cutting delivery miles by 23% for a Bristol-based client.

Secure Transactions and Dispatch

Integrated payment gateways authorise transactions while generating shipping labels. A Lancashire manufacturer slashed dispatch delays by 41% through automatic carrier selection. Customers receive tracking updates before warehouse teams even pack materials.

These modular components adapt as your business grows. Start with basic validation tools, then add advanced routing as order volumes increase. The right configuration becomes your silent efficiency partner – working round-the-clock to protect margins and reputation.

How Order Processing Automation Enhances Efficiency

Mistakes in handling transactions can silently drain your profits. Modern electrical enterprises achieve 40% faster turnaround by eliminating manual steps. Our implementations show automated workflows not only prevent costly slip-ups but create ripple effects across operations.

Minimising Human Errors and Data Entry Issues

Typographical slips in invoices or stock codes cost UK electrical firms £23,000 annually on average. Real-time validation tools cross-reference entries against live databases, flagging mismatches instantly. A Midlands supplier reduced pricing discrepancies by 78% within six weeks of implementing these checks.

Consider how automated capture works: customer requests flow directly into your system, bypassing spreadsheets entirely. One Bristol wholesaler cut rework hours by 63% through this approach. Staff now focus on resolving complex queries rather than correcting basic input mistakes.

Accelerating Order Fulfilment and Delivery

Speed matters when contractors need materials by tomorrow morning. Automated routing slashes approval bottlenecks – a Glasgow distributor reduced fulfilment from three days to five hours. Their system now prioritises local stock and assigns couriers based on real traffic data.

Same-day dispatch rates jumped to 94% for a Surrey manufacturer using intelligent labelling tools. Customers receive tracking numbers before warehouse teams finish packing. This precision builds trust – 82% of buyers report higher satisfaction with suppliers offering real-time updates.

Implementing Your Automated Order Processing System

Successfully adopting digital workflows requires careful planning and execution. We guide electrical firms through three critical phases: process evaluation, software selection, and tailored implementation. Our approach ensures your transition delivers measurable improvements without disrupting daily operations.

Evaluating Existing Processes and Setting Goals

Start by mapping your current workflow from quote to delivery. Identify bottlenecks like delayed approvals or manual stock checks. A Midlands contractor discovered 37% of their staff time was spent re-entering data across platforms – a clear candidate for improvement.

Set SMART targets aligned with business priorities:

- Reduce invoice errors by 75% within 90 days

- Achieve 98% same-day dispatch rates

- Cut operational costs by 15% in Q1

Selecting the Right Software and Customising Workflow

Choose platforms that integrate with your existing ERP and CRM systems. Look for:

- Real-time inventory sync across warehouses

- Mobile-friendly interfaces for field teams

- Customisable approval chains

“We rolled out changes in phases – starting with basic validation tools before activating advanced routing. This let our team adapt without overwhelm.”

Pilot new systems with a limited product range first. A Bristol wholesaler tested their configuration with 12 SKUs, refining workflows before full deployment. Regular training sessions ensure staff confidence with updated processes.

Remember: implementation isn’t a one-off project. Schedule quarterly reviews to optimise settings as your business evolves. The right setup grows with you, delivering continuous improvements in speed, accuracy, and customer satisfaction.

Integrating Systems and Leveraging Advanced Technology

When was the last time your business software truly worked together? Siloed tools create friction that costs UK electrical firms an average of 14 working days annually. Our implementations show that unified platforms boost productivity by 37% while reducing data reconciliation headaches.

Seamless Integration with ERP, CRM and Other Tools

True digital transformation happens when systems speak the same language. We connect your order management platform to:

- Accounting software for real-time margin tracking

- Warehouse management systems for ‘live’ stock updates

- Supplier portals for automatic replenishment alerts

A Midlands wholesaler eliminated 23 hours weekly by linking their CRM to dispatch teams. Sales reps now access live delivery ETAs during client calls. This integration slashed customer service queries by 41%.

| Integration Approach | Time Saved Weekly | Error Reduction |

|---|---|---|

| Basic API Links | 8 hours | 54% |

| Custom Middleware | 19 hours | 78% |

| Cloud-Native Platforms | 27 hours | 92% |

Best Practices for System Customisations

Tailoring doesn’t mean rebuilding from scratch. Follow these principles:

- Map workflows before configuring settings

- Preserve core functionality while adding niche features

- Test changes with pilot product lines first

“We used low-code tools to create a custom approval chain for large orders. Now our finance team reviews £10k+ transactions automatically.”

Remember: Over-customisation creates update nightmares. One Bristol distributor needed six months to migrate their bespoke system. Balance uniqueness with maintainability – your future self will thank you.

Monitoring, Optimising and Measuring Success

Effective digital workflows demand constant refinement. Leading UK electrical firms now track 14+ performance metrics weekly, with 68% reporting measurable efficiency gains within 90 days. Real-time dashboards transform raw numbers into actionable insights – your silent quality control partner.

Key Performance Indicators and Operational Metrics

Focus on these critical measurements:

- Fulfilment speed: Time from request to dispatch (aim for

- Accuracy rates: Error-free documentation percentages (target 99.8%+)

- Customer satisfaction: Post-delivery feedback scores (benchmark 4.7/5)

A Birmingham distributor improved on-time deliveries by 33% after monitoring carrier performance data. Their system now flags underperforming couriers before customers complain.

Data-Driven Strategies for Continuous Improvement

Monthly review sessions unlock hidden potential. One Manchester wholesaler reduced stockouts by 41% through:

- Analysing seasonal demand patterns

- Adjusting safety stock thresholds

- Automating supplier replenishment alerts

“Our weekly KPI reports revealed a 19% delay in weekend processing. We reallocated team resources and now achieve consistent service levels.”

Combine quantitative data with staff feedback. Field teams often spot workflow hiccups before systems flag them. This dual approach helped a Leeds manufacturer slash returns by 62% through targeted packaging improvements.

To Sum Up

The electrical sector’s future belongs to businesses embracing intelligent solutions. Manual methods can’t match the precision modern buyers demand, nor the 63% error reduction our clients achieve through digital workflows. Real-time stock tracking and seamless system integration aren’t luxuries; they’re survival tools in today’s £14.3bn UK market.

We’ve seen streamlined operations transform electrical firms nationwide. Same-day dispatch rates climb. Customer satisfaction scores soar. Labour costs shrink as teams focus on strategic tasks rather than data rekeying. These aren’t hypothetical benefits – they’re measurable outcomes for forward-thinking businesses.

Your competitors aren’t waiting. Contractors now prioritise suppliers offering instant confirmations and flawless documentation. Can your current setup deliver? We help electrical enterprises implement robust systems that grow with their needs, from basic validation tools to advanced AI-driven workflows.

Ready to future-proof your operations? Check out our electrical customer acquisition suite to start growing your business today.

Let’s discuss how tailored solutions can slash costs while boosting service quality. The first step towards smarter order management starts with a conversation – and we’re here to listen.